What is Porosity?

Why is Porosity important to air filters using foam media?

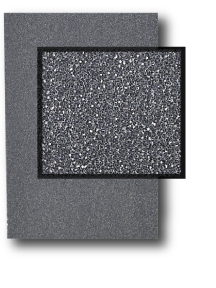

Open cell, reticulated, Polyurethane foam is a great material for filtering unwanted particulate from the air. It has a pentagonal, dodecahedron geometric shape that is controlled in the manufacturing process and may be varied to meet specific applications. These shapes are referred to as pores. The term porosity, measured in PPI (Pores Per Inch) designates the number of pores in one linear inch. Counting the pores is a visual indication of porosity which directly coincides with an airflow tested measurement that defines a range of airflow for a given porosity.

What does all this mean to you and your air filter application? In general, with thickness being equal, the higher the porosity, the more pressure it takes to pull or push air through the foam filter media. For example, 10 PPI foam has large pores, approximately 0.10” in diameter and offers very little resistance to airflow. Consequently, it is not very effective at capturing small particles and arrestance values are typically below 50%. By comparison, 60 PPI foam, has small pores, approximately 0.015” diameter. The resistance to airflow can be quite high, especially if thickness is greater than 0.50”. However, arrestance values can reach well into the 90% range. The average home furnace filter ranges from 65% to 90% arrestance.

Air filters use reticulated foam media, capture dust particles by obstructing their path and causing them to become captured in the cellular structure. By varying the depth of the foam filter media, you can enhance the ability for dust to “depth load” instead of merely “face loading” like higher MERV rated paper and synthetic media Face loading increases pressure drop more rapidly than depth loading. Foam filter media is offers the added benefit of being cleanable by vacuum and washing with warm water.

To determine the porosity needed for your application, you must first decide what arrestance value you need. In other words, what percentage of the airborne dust do you need to capture? You will also need to take into account how much pressure drop you have available in your fan system. UAF offers filter foam in 10, 25, 45, 60 and 80 PPI and can slice the media as thin as 0.125” thick to help dial in the exact media for your application.